The future is bright, but it’s not ours to see.

-Doris Day, Que Sera, Sera (1956), song

An Exciting New Initiative!

I am extremely excited to say that my research in Thermal Management of EV Power Electronics using Metallic Phase Change Materials was selected as part of the first ever cohort of graduate students to be funded by the University of Toronto’s Climate Positive Energy (CPE) Initiative.

This initiative’s goal is to link science, social science, engineering, economics and policy researchers to transform our energy systems, and I could not be more grateful to the committee for this opportunity. I’d like to send my humblest thanks to my supervisors Professor Cristina H. Amon and Professor Sanjeev Chandra for their support and guidance. I’d also like to thank all my lab mates who inspired me throughout this process 😊. Here’s me on our lab website yay!

In the future, I hope to participate via a research presentation, in at least one Climate Positive Energy workshop, so look out for that post when it comes, dear readers.

Update: It happened! Link for the post!

My Research Proposal

Below I present the unedited research proposal I submitted to the Climate Positive Energy Committee for their consideration. I’m finding that research directives can change over time, but this still largely captures the essence of my work.

Background:

With increasing charging speeds and higher power demands in electric vehicles (EVs), it becomes increasingly challenging to manage the waste heat generated by the EV power electronics [1]. These small chip-like devices manage the flow of electrical energy within the vehicle and become dramatically less efficient (even failing catastrophically) at high temperatures. At the same time, federal governments, energy companies, and manufacturers have set goals to increase the power density of power electronic subsystems by over 5x in the coming years to make charging quicker and more convenient for end users [2]. This immense pressure to shrink is pushing traditional, steady-state cooling systems to the limit; however, these systems are also generally intended for worst-case conditions and tend to be overdesigned compared to the average heat loads [1]. The time-varying nature of power electronic systems makes them wellsuited to novel transient thermal management strategies [3], [4]. One transient strategy involves the use of phase change materials (PCMs), which can absorb excess heat by melting during a transient heat spike while maintaining a nearly constant temperature [5]. PCMs offer a simple, passive solution to thermal management and have been adopted in building applications; however, little research has explored their use for power electronic applications and experimental verification of these studies is even more sparse [5].

Research Objectives:

My research investigates the use of metallic PCMs for transient thermal management in high heat flux scenarios. These materials offer an inherently high thermal conductivity, making them well-suited for managing the sharp transient heat spikes expected in EV power electronics. My objectives are to develop a design methodology for PCM-based cooing solutions using a combination of numerical simulation and analytical techniques. I will then experimentally validate this methodology by designing a PCM-based cooling solution for a 100 kW EV fast-charger in a multidisciplinary project in collaboration with the University of Toronto EV (UTEV) research center. Finally, to enable a more effective codesign process, I will also develop a novel, reduced-order transient electro-thermal simulation tool. This work falls under the “carbon” theme of the CPE as it focuses on enabling the next generation of EV fast-charging infrastructure and the continued electrification of the global vehicle fleet.

Work Plan:

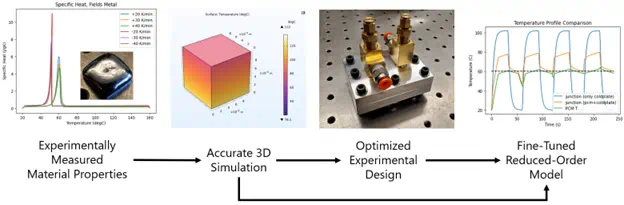

So far, I have designed and tested an early version of my cooling solution for low heat flux conditions and developed detailed 3D simulations using the experimentally measured properties of several candidate PCMs. I have also developed the first iteration of a reduced-order model for PCM-based cooling solutions. The next stages of my work will involve refining my simulation to study the characteristics of PCM-based cooling solutions and how their cooling performance can be increased. I will also refine my experimental setup to demonstrate effective cooling at significantly higher heat fluxes. Using this combination of numerical and experimental data, I hope to fine-tune my reduced order model and integrate it into a comprehensive electro-thermal codesign tool. This overall work plan is illustrated below in Figure 1.

References:

[1] G. Moreno, S. Narumanchi, X. Feng, P. Anschel, S. Myers, and P. Keller, “Electric-Drive Vehicle Power Electronics Thermal Management: Current Status, Challenges, and Future Directions,” J. Electron. Packag., vol. 144, no. 1, p. 011004, Mar. 2022, doi:10.1115/1.4049815.

[2] “US DRIVE Electrical and Electronics Technical Team Roadmap,” Energy.gov. https://www.energy.gov/eere/vehicles/downloads/us-drive-electrical-andelectronics-technical-team-roadmap (accessed Oct. 28, 2021).

[3] H. P. de Bock et al., “A System to Package Perspective on Transient Thermal Management of Electronics,” J. Electron. Packag., vol. 142, no. 4, p. 041111, Dec. 2020, doi: 10.1115/1.4047474.

[4] J. Mathew and S. Krishnan, “A Review On Transient Thermal Management of Electronic Devices,” J. Electron. Packag., Jan. 2021, doi: 10.1115/1.4050002.

[5] P. J. Shamberger and N. M. Bruno, “Review of metallic phase change materials for high heat flux transient thermal management applications,” Appl. Energy, vol. 258, p. 113955, Jan. 2020, doi: 10.1016/j.apenergy.2019.113955.